IMAGE JUNCTION SDN BHD

782029-W

[Southern] Johor

No. 15, Jalan Selatan 3, Taman Perindustrian Ringan Pulai, 81300 Skudai, Johor, Malaysia.

+6016-733 3606

IMAGE JUNCTION SDN BHD

782029-W

[Central] Negeri Sembilan, KL & Selangor

No.28, Jalan Equine 9C, Taman Equine, 43300 Seri Kembangan, Selangor, Malaysia.

+6016-7133605 (William)

info@imagejunction.com.my

IMAGE JUNCTION SDN BHD

782029-W

[Northern] Perak, Penang,

Perlis & Kedah

07-3-69 D'Piazza Mall, Jalan Mahsuri, 11900 Bayan Baru, Penang, Malaysia.

(Temporary closure. We are moving to a new location in soon.)

IMAGE JUNCTION SDN BHD

782029-W

[East Coast] Pahang,

Terengganu & Kelantan

Lot 2581, Taman Adis Indah Tok Adis, Kuala Ibai, 20400 Kuala Terengganu, Terengganu, Malaysia.

+6016-2013605

+6016-7715605

IMAGE JUNCTION (SABAH) SDN BHD

878274-W

[East Malaysia & Brunei]

Sabah , Sarawak & Brunei

Shoplot No 9, Block D, Ground Floor, Putatan Platinum Plaza, 88200 Putatan, Sabah, Malaysia.

+6016-716 3606

+6016-886 3605

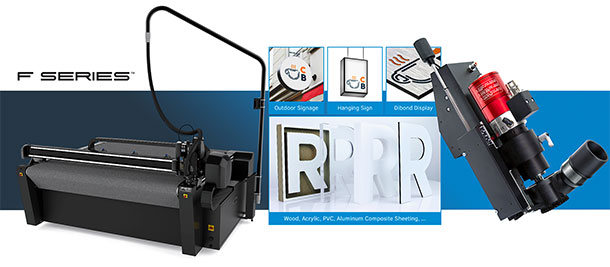

Summa F-SERIES FLATBED CUTTING SYSTEM

| Previous | 3 / 4 | Next |

F series Promo videoSumma Success Story @ Vision DisplaySUMMA F SERIES finishing system Man vs MachineMaking Special Honeycomb Standee Design For F&B

Download Files

202111-f-series-brochure-en-lowres.pdf (5.52 MB)SUMMA_WALL_DISPLAY_MODULES_&_TOOLS_CHART.pdf (12.75 MB)

AVERY_X_SUMMA_TRAFFIC_SIGN.pdf (1.03 MB)

.png)

The most versatile flatbed cutting system ever

Summa’s Professional Flatbed Finishing System is an award-winning solution for producing innovative signage, displays, samples, packaging applications, and more. With an ever increasing arsenal tools and optional add-ons, this is the breakthrough cutting solution you’ve been dreaming about.

Features

Industry-leading features and optional add-ons.

.jpg)

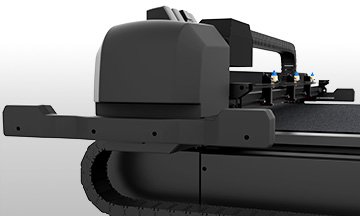

Multifunctional Head

The multifunctional head holds up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

.jpg)

Powerful Tangential Module

Offers a vertical force of 10 kg and corresponds to a wide range of matching tools. Each tool has a barcode identifier that ensures automatic recognition and parameter settings.roller

.jpg)

Media Advance Clamps

Pneumatically-driven media advance clamps hold the material down while pulling it forward in order to work continuously in panels or multiple jobs.

.jpg)

.jpg)

Barcode

The barcode workflow automatically identifies the job to obtain the necessary cutting data from the computer. Scanning the job happens automatically by the built-in camera of the Summa F Series system or by a handscanner, depending on the selected workflow.

.jpg)

Advanced Safety System

The advanced Safety System, delivered with all F Series models, guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

.jpg)

ADC

The Automated Depth Control (ADC) simplifies tool, knife or bit changes significantly. The ADC measures the tip of the knife or bit accurately and sets the down position of the tool to the level of the table. This ensures the best settings can always be used to get the most optimal cut quality.

.jpg)

Accelerated workflow with F-Performance

Increase the performance of your F Series flatbed system with almost 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cutting tool.

.jpg)

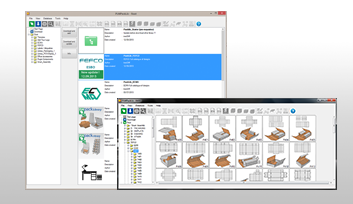

PackLib

The PLM PackLib for Summa is a library of resizable standard packaging models. The most popular packaging standards FEFCO (corrugated cardboard) and ECMA (folding carton) are included. Also a few POS display designs and solid cardboards (furniture) designs are available.

.jpg)

GoProduce software to perfectly match your F Series

The software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible

.jpg)

.jpg)

The Twin Workflow combines the strengths of a Summa vinyl cutter – S Class 2 or S One Series - and an F Series flatbed cutter. This translates into two cutters that are perfectly matched. In this way, you double your productivity and speed up your delivery times by up to 47%

.jpg)

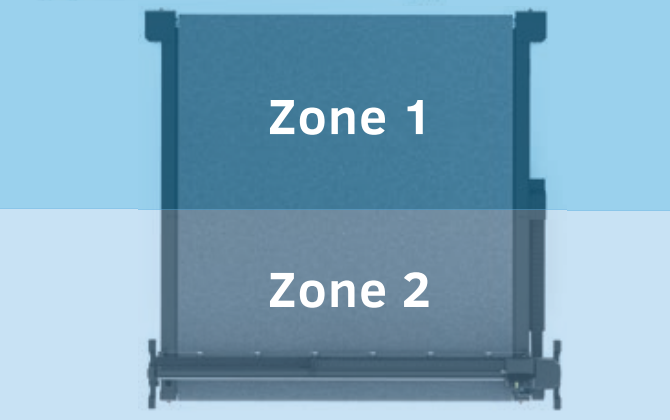

Summa Tandem Mode

Tandem Mode for F1432, F1832, F3232 By using the front zones and rear zones alternately, this feature leads to significant production increase. With the Tandem Mode, the active working area on the flatbed can be divided into front and back processing areas, enabling the user to load and unload material on one end of the table while cutting material on the other end of the table. This will avoid idle periods during cutting, which will add significant value to the overall workflow.

.png)

.jpg)

(Optional) Conveyor extension to minimize downtime

The conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Note: image to be updated to F1612 with safety system.

.jpg)

(Optional) Heavy-Duty Roll Support

The optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

.jpg)

.jpg)

BACK SIDE CUTTING EDGE DETECTION

GoProduce 1.10* enables the user to perform backside cutting with edge detection. This new feature is bound to save the user valuable time, expand your job possibilities and protect your print. A new camera profile is set to read the marks and detect the edges to locate the position of the sheet.

.jpg)

(Optional) SAi Box and Display Software

SAi Box and Display is the ideal product for businesses looking to quickly and easily design custom corrugated boxes and packages. Box and Display box design software includes ready-to-use three-dimensional design templates for folding carton, corrugated plastic, cardboard and honeycomb rigid material to simplify structural design of boxes, packages and corrugated POP-displays.

Explore Further

An array of possibilities within every module and tool.

.jpg)

.jpg)

.jpg)

(3).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.gif)

![]()

![]()

Download more tools & bits information:

.png)

Big, Bigger, Biggest

Available in 5 sizes to dramatically increase productivity.

.jpg)

Brochure

![]()

Click for download